The ATALAYA / LAIN TECH pilot is set to drive innovation in sustainable mining by integrating a SME-developed green technology aimed at extracting strategic raw materials — including copper (Cu), zinc (Zn), cobalt (Co) and platinum group metals (PGMs) — from low-grade ores. The initiative is led by consortium partners Atalaya Mining and Lain Tech, combining industrial expertise with cutting-edge technological development to advance eco-efficient resource recovery in Europe.

E-LIX Technology for Sustainable Metal Recovery

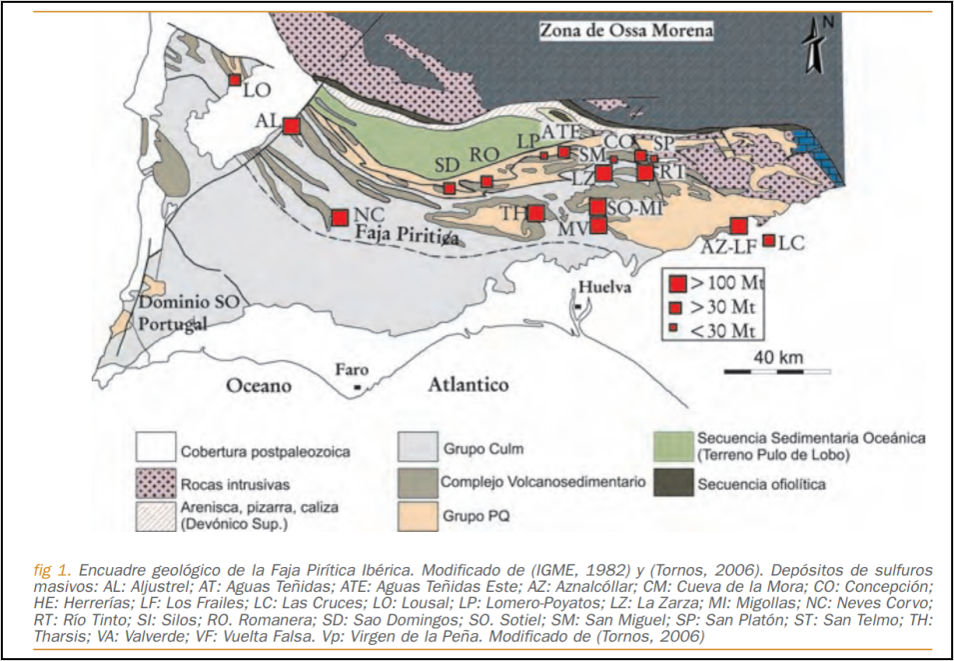

Unlocking the Power of Hydrometallurgy in the Iberian Pyrite Belt

The Atalaya–Lain Tech pilot, developed under the I4-GREEN framework, showcases a breakthrough in sustainable hydrometallurgical processing for the recovery of essential metals, such as copper (Cu) and zinc (Zn). Set in the Iberian Pyrite Belt, one of the richest sulphide deposits globally, the project is pioneering the E-LIX™ technology—a unique process that dissolves complex sulphide concentrates, followed by solvent extraction and electrowinning (SX-EW).

“The Iberian Pyritic Belt (IPF), with more than 1,600Mt of massive sulfides originally in place, is one of the most important metallogenic provinces with the highest concentration of sulfides in the world” IGME

This innovation successfully overcomes the long-standing challenge of passivation in sulphide leaching, offering a commercially viable and environmentally sound alternative for low-grade, polymetallic ores. It sets a new standard for green extraction methods in mining.

Industrial Validation and Results

The pilot plant, located at the Riotinto Project, has completed its commissioning phase, producing the first copper and zinc cathodes alongside their intermediate products. These results confirm that the system functions as designed and is capable of treating various concentrates with distinct mineralogies.

Key performance indicators achieved include:

- Validation at industrial scale with consistent metal recovery.

- Testing of multiple reagents to optimise recovery of critical raw materials (CRMs) such as silver (Ag), lead (Pb), cobalt (Co), and platinum group metals (PGMs).

- Transformation of deleterious elements like arsenic and bismuth into valuable by-products.

The pilot proves the system’s flexibility and scalability across various deposits, potentially extending the life of mining operations from 13 to 60 years.

Environmental Sustainability and Green Impact

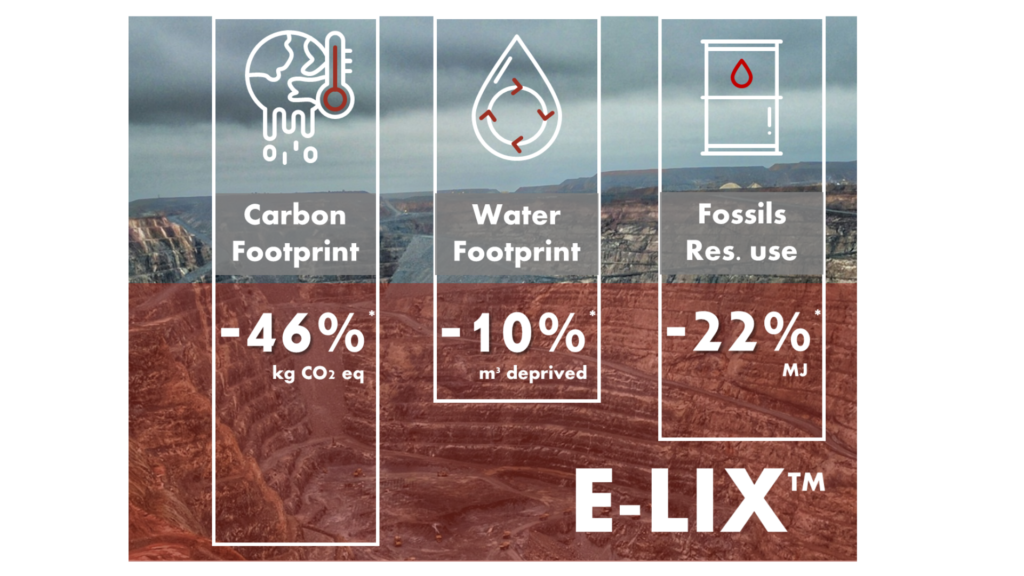

The E-LIX process has demonstrated a substantial environmental advantage over conventional methods. By implementing no fossil fuel usage and adopting circular resource strategies, the project achieves up to 90% CO₂ emission avoidance.

Additionally, according to the ISO 14040-compliant Life Cycle Assessment:

- Carbon footprint reduction: –46% per tonne of feed.

- Water use reduction: –10%.

- Fossil resource use reduction: –22%.

These reductions contribute directly to the EU’s Green Deal objectives, positioning E-LIX as a model for responsible sourcing and sustainable mining in Europe.

Social and Economic Impact

The pilot’s success brings tangible benefits to the Andalusia region and beyond. With an estimated potential of creating up to 300 direct jobs, it fosters local economic development while strengthening Europe’s strategic autonomy in raw materials. The project has also laid the groundwork for E-LIX 2.0, a full-scale industrial plant that would multiply these impacts.

The Government of Andalusia has classified the project as strategic, actively supporting its acceleration and regional implementation. Cross-border interest is also growing, particularly in Portugal, where studies explore replicating the technology in similar deposits and tailings.

Replicability and Future Deployment

E-LIX is more than a pilot — it is a scalable and transferable solution for sustainable metal recovery from complex ores across Europe. Its modular process design allows adaptation to different feedstocks, enabling broader application in the recovery of:

- Copper, zinc, silver, lead, cobalt and PGMs.

- Hydrogen production as a by-product, contributing to clean energy goals.

With demonstrated success in real industrial settings, E-LIX stands ready for replication throughout the Iberian Pyrite Belt, and its methodology has potential application in other metallogenic regions globally.